Electrical Bearing Protection Q&A Part 14

Part 14 in a series of questions and answers from our Q&A webinars.

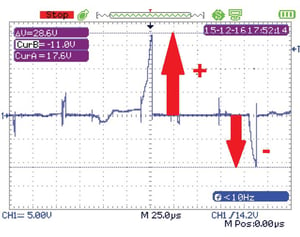

Q1: Does the discharge current oscillate polarity? I often see shaft voltage plots with what looks like positive and negative discharge spikes.

A1: Short answer: yes. We focus on the "positive" discharges (center in the figure) because it's intuitive to think of something unstable "building up" and then crashing back to the ground. In fact the motor shaft and rotor can be positive or negatively charged relative to the frame. Regardless of the shaft voltage polarity, damage will be done if it arcs through the bearings.

Q2. Is the grounding ring appropriate for a dusty environment like a mine, or could accumulated dust interfere with its function?

A2: AEGIS® rings have been used inside plenty of mines and paper mills. These are some of the dustiest, dirtiest environments on earth.

The rings are resilient against moderate amounts of dust. Their fibers tend to sweep the motor shaft clean. In dirtier environments, you can also slip an O ring up the shaft, or use a slinger or other protective cover. If that's not enough, the AEGIS ring can always be installed inside the motor, either by the manufacturer or by a motor repair contractor.

Q3. What are the pros and cons of AEGIS rings compared with inductive absorbers?

A3: We answered a related question in our last Q&A about inductive filters inside of drives. In brief, AEGIS rings and inductive absorbers do different things, and protect against different things.

There are three ways VFDs can damage motor bearings: #1, shaft voltage discharge current, #2 high-frequency circulating current, and #3 rotor ground current. Shaft voltage discharge is a problem in all motors on drives. It is caused by the common mode voltage of the drive's output. Circulating currents are only a problem in larger motors, over 100 hp (75 kW), and rotor ground current is a problem when the motor is not well-grounded. These two are caused by common mode current in the drive's ouptut.

AEGIS rings primarily protect against shaft voltage discharge, #1. Inductive cores protect against #2 and #3. These chokes reduce peak common mode current, but they barely affect common mode voltage. But the common mode voltage is what produces the shaft voltage. So while inductive absorbers reduce bearing currents #2 and #3, they do not do not protect against #1.

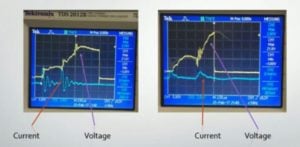

This is clear in the shaft voltage readings below. On the left is a motor without an inductive absorber. The shaft voltage (yellow) builds up and then collapses. That collapse means an arc through the bearing. On the right is a motor with an inductive absorber. The shaft voltage builds up and again, discharges by arcing through the bearing.

Shaft voltage without (left) and with (right) an inductive filter. Shaft voltage builds up and arcs through the bearing either way.

Shaft voltage without (left) and with (right) an inductive filter. Shaft voltage builds up and arcs through the bearing either way.Common mode chokes or inductive absorbers cannot protect against shaft voltage discharge current. If you use chokes, you need a second type of protection against bearing current #1. There are many options, but an AEGIS Shaft Grounding Ring is usually the most practical.

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.