Electrical Bearing Protection Q&A Part 1

We have been presenting regular training webinars on preventing electrical bearing damage for about two years now. We've recently begun hosting question and answer sessions as well, where attendees can ask questions of the AEGIS Expert on Duty. These Q&A webinars have been very popular.

In this new series, we'll be sharing viewer questions, and our answers, from these webinars.

Q: I've done work in a hospital where every pump motor was on an ABB drive. They had a massive bearing fluting problem. Could this be an ABB problem, or just a typical overcrowded hospital mechanical room with inadequate grounding?

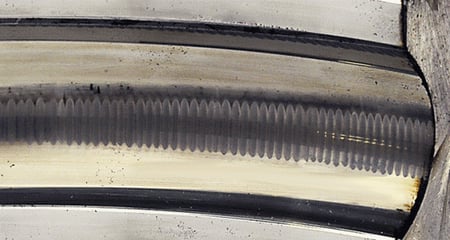

Motor bearing fluting damage caused by VFD power

Motor bearing fluting damage caused by VFD power

A: The problem is definitely NOT specific to ABB, or any other manufacturer. Fluting happens to motors on all brands of drive. We don't know of any exact statistics, but we estimate that something like 50% of all unprotected motors on drives will get it.

Whether electrical bearing damage happens or not is partly random. But there are known contributing factors. Having a poor frame-to-ground connection can definitely make it worse.

As for the room's ground, a mechanical room should have less than 5 ohms resistance. You should definitely test the ground quality, or have a contractor do it, because if the resistance to ground is too high, then AEGIS rings won't work. If you had 50 ohms, say, between the room and the building ground, that's not good.

The next step would be to check the individual motors' grounds. If those have high resistance, you might try a high frequency grounding strap. Common mode chokes or cores can also help.

Q: Does using a grounding ring also require a grounding strap?

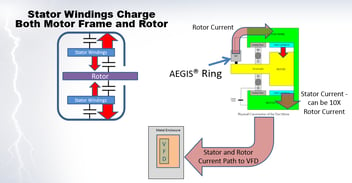

A: Not necessarily, but we recommend it. There are two things going on here. First, there's current flowing through the ring from shaft voltage, and you want to give it the easiest path to ground that you can.

Second, grounding straps reduce another kind of bearing current, called rotor ground (RG) current. (Some people confusingly call this "shaft grounding current.") You get RG current when the motor is less well-grounded than the equipment it's driving. This damages the motor's bearings and can damage the equipment's bearings too. In this situation, you want to electrically bond the motor frame and the equipment, and you do that with a grounding strap. This way, current flows from the motor frame through the strap to the equipment, instead of arcing through the motor bearings and moving down the shaft to it.

Q: I've found that fluting is more prevalent in motors in older facilities, as opposed to new construction. Retrofitting may overwhelm existing grounds. Do you have any evidence or experience with this?

with this?

A: There's not 100% correlation here, but if you have a 30 year old building & you install drives, you're going to use what's already there. Old, degraded grounds will have higher resistance and make stray currents more likely. Contrast this with a new building, where drives are specified upfront. In new construction, the grounding & other systems will be specified to be able to stand up to drive power.

Q: What information do I need to specify AEGIS Shaft Grounding Rings for motors on variable frequency drives?

A: All of the information you need is on our specs page here. The first pdf listed there has our recommended specification language. The second is a copy of the CSI's Division 23 section 05 13, Common Motor Requirements for HVAC motors, with our best practices added in.

Q: I once specified shaft grounding rings for industrial fans. Due to leadtime, the contractor asked if he could use a magnetic core instead. How do these cores work, & are they a suitable substitute for grounding rings?

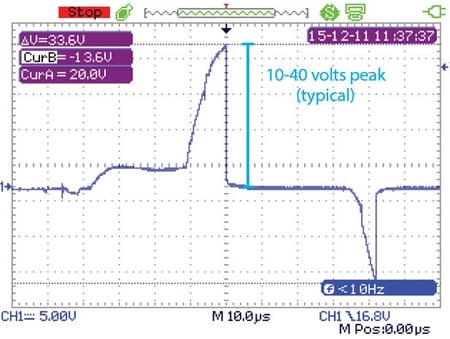

Without shaft grounding, shaft voltage builds up and then collapses by arcing through the bearing. Common mode chokes do not affect this process.

Without shaft grounding, shaft voltage builds up and then collapses by arcing through the bearing. Common mode chokes do not affect this process.

A: These cores are common mode chokes.

This gets pretty technical, so we are going to devote an entire blog post to it. For now, the short answer is:

Chokes reduce rotor ground currents in poorly grounded motors, and high frequency circulating currents in large motors (100 hp/75 kW plus). But they DON'T reduce capacitive shaft voltage, so you still get arcing through the bearings. We've got videos of this. The videos show a motor with common mode chokes, and you can see the shaft voltage slowly rise and then suddenly drop, which means that it's arcing through the bearing. That's going to cause damage. You don't see this buildup and discharge with AEGIS rings. AEGIS keeps the shaft voltage too low to arc through the bearing.

As for rotor ground and circulating currents, chokes probably do at least reduce damage. There are unbiased experts who recommend them for these types of bearing current. Some of their manufacturers' and distributors' claims are questionable, though, and we should point out that chokes do not come with a warranty against bearing damage.

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.