Another Reason to Use VFDs for Motor Control

Most articles about the benefits of variable frequency drives (VFDs) focus on two things: Energy efficiency, and fine control. Which is fair enough. VFDs can save energy by only providing as much power as a motor needs. Think fans blowing at half speed, or an unloaded conveyor belt. Speaking of conveyor belts, VFDs can control torque when the load changes - like suddenly adding a heavyweight to a conveyor. So VFDs also allow smooth, steady operation under changing load.

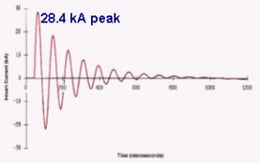

But VFDs also limit inrush current, which rushes through the motor when it's first energized. When a motor is started on line voltage, the inrush current may be two to ten times the normal operating current. This can cause electrical and mechanical damage to the motor (and coupled equipment). Jerry Muehlbauer of Marathon Motors compared this effect to "starting your car while on jack stands: Put it in gear, start the engine, place a brick on the gas pedal, and then push it off the jack stands. This results in uncontrolled acceleration & huge mechanical stress on the transmission and engine." [Editor's warning: Do not try this.]

first energized. When a motor is started on line voltage, the inrush current may be two to ten times the normal operating current. This can cause electrical and mechanical damage to the motor (and coupled equipment). Jerry Muehlbauer of Marathon Motors compared this effect to "starting your car while on jack stands: Put it in gear, start the engine, place a brick on the gas pedal, and then push it off the jack stands. This results in uncontrolled acceleration & huge mechanical stress on the transmission and engine." [Editor's warning: Do not try this.]

When a motor is started on a VFD, the drive slowly and smoothly increases the current from zero up to the normal operating level. This avoids all of the stress inrush currents cause.

There are other ways to protect motors from inrush currents. Some of them are cheaper, but none offer VFDs' other benefits. So the choice depends on the price difference and how important VFDs' energy savings and smooth operation are to you.

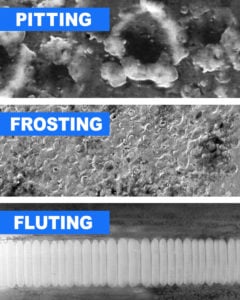

If you do opt for VFD control, be sure to also protect the motor bearings from the VFD itself. VFDs produce voltage on the shafts of the motors they control. This voltage can discharge by arcing through the bearings, causing electrical bearing damage and premature failure. You can prevent this failure by using AEGIS® Shaft Grounding Rings to bleed off the shaft voltage before it can arc through the bearings. (For motors over 100 hp, the best practice is to install one insulated bearing to interrupt circulating currents, along with an AEGIS ring.)

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.