Conveyor Motors on Drives Need Bearing Protection

Variable frequency drives, or inverters, are often used to control conveyor motors. In some cases, the drive is used as a soft starter. Conveyors often stop and start frequently. Frequent starts and stops online power are bad for motors. Firstly, large inrush currents cause thermal damage. They also cause torque spikes (jerking), which can break belts. With a drive, speed can smoothly be brought up from zero to the full operating speed. VFDs also afford precise speed control. This is especially important in applications like food and beverage processing and bottling. This ability also helps prevent sudden changes in speed when a large weight is suddenly added to or removed from a conveyor.

Variable frequency drives, or inverters, are often used to control conveyor motors. In some cases, the drive is used as a soft starter. Conveyors often stop and start frequently. Frequent starts and stops online power are bad for motors. Firstly, large inrush currents cause thermal damage. They also cause torque spikes (jerking), which can break belts. With a drive, speed can smoothly be brought up from zero to the full operating speed. VFDs also afford precise speed control. This is especially important in applications like food and beverage processing and bottling. This ability also helps prevent sudden changes in speed when a large weight is suddenly added to or removed from a conveyor.

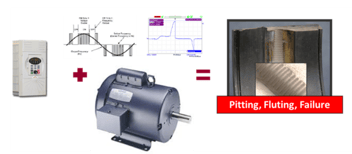

through the bearing.

But these drives have their downsides, including electrical bearing damage. Drives generate voltage on motor shafts, and that voltage causes arcing through the bearings. This can cause premature bearing failure, and unplanned downtime while the motor is being repaired or replaced. For motors under 100 hp (75 kW), the solution is the AEGIS® Shaft Grounding Ring.

AEGIS rings bleed off the shaft voltage before they can arc through the bearings. Several major motor manufacturers have product lines with AEGIS rings factory-installed. AEGIS rings can also be added as a mod, and can always be retrofit onto motors.

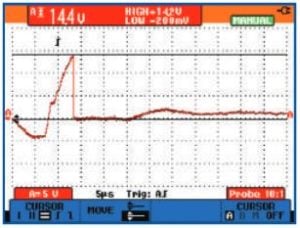

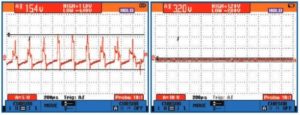

A few years back, we visited a large Midwestern airport to check their conveyor motors for shaft voltage. We checked two NEMA Premium® motors that were rated "inverter ready," but did not include shaft grounding. Both of them showed high shaft voltage, and one showed clear signs of arcing. As a test, we installed AEGIS rings on both motors. The shaft voltage was reduced from about 15 volts (peak to peak) to a safe level of 3 volts, and there was no sign of further destructive arcing.

The scale is the same in both images.

The results were clear: AEGIS rings allow conveyor motor users to get the benefits of inverter control, without the risk of premature bearing failure.

AEGIS Shaft Grounding Rings also have a 2-year extended warranty against bearing fluting damage. No other form of shaft grounding offers a warranty like this.

![]()

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer both live webinars and on-site lunch-and-learn trainings.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection - for motors and generators - sign up for a training. We offer monthly live training webinars, and we can also visit your facility to review your exact application.

![]()

AEGIS Shaft Grounding Rings will be on display at the WEFTEC 2019 Technical Exhibition in Chicago this September 23-25th. Stop by Booth 7453 and meet the team, see a live demonstration of how AEGIS rings reduce shaft voltage, and pick up a copy of the Bearing Protection Handbook. See you at the show!