Why Should You Care About the Total Cost of Owning an Electric Motor?

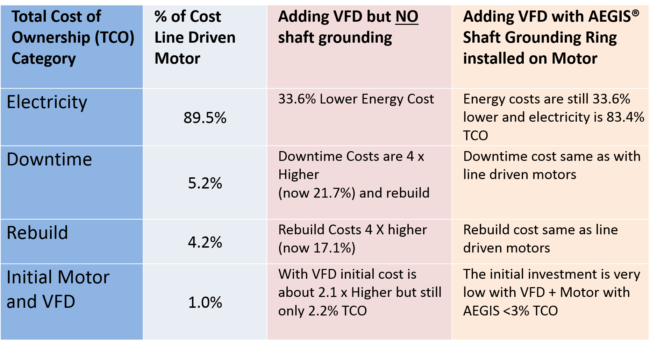

Last month, we discussed Volume 3 of the 2021 MSMA report on potential savings through improved efficiency. Let's expand on how you can apply the findings of that report. Did you know that the cost of electricity is 90% of the total cost of owning an electric motor for a period of 20 years? The remaining 10% is the cost of the motor itself (1%), downtime (5%), and re-build costs (4%), as estimated by the U.S. Department of Energy.

So here is where variable frequency drives (VFDs) come in: Using a VFD to drive an electric motor can save energy, usually 30-50% or more, especially in applications with varying loads. With VFDs, motors do not need to run at full speed but can be run at the most efficient speed. With a drive, you can save energy and eliminate wasteful mechanical throttling and damping.

For example, even a 20% reduction in fan speed can reduce energy consumption by nearly 50%. In fact, reducing a fan's speed by half cuts the horsepower needed to run it by a factor of 8! So you can easily see that adding a VFD to a system can save a tremendous amount of energy and, therefore money.

What If There are Other Hidden Costs?

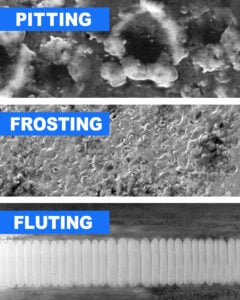

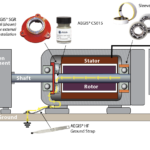

What if the energy efficiency increases, but uptime and reliability suffer? Then the energy savings vanish! Shaft voltage and bearing current induced by VFDs can wreak havoc with motor bearings, dramatically shortening motor life and causing costly repairs, often repeatedly, over the lifetime of the motor. To mitigate these currents and realize the full potential of VFDs, a reliable method of shaft grounding is essential. We will therefore compare three Total Cost of Ownership scenarios:

What if the energy efficiency increases, but uptime and reliability suffer? Then the energy savings vanish! Shaft voltage and bearing current induced by VFDs can wreak havoc with motor bearings, dramatically shortening motor life and causing costly repairs, often repeatedly, over the lifetime of the motor. To mitigate these currents and realize the full potential of VFDs, a reliable method of shaft grounding is essential. We will therefore compare three Total Cost of Ownership scenarios:

- Line driven motor (no VFD)

- VFD driven motor with no shaft grounding ring (bearing protection) installed

- VFD driven motor with a shaft grounding ring installed

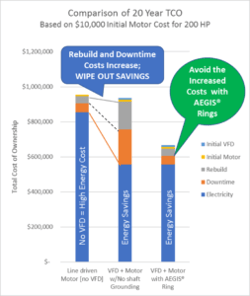

So here is an example: Let's say you pay $10,000 for a 200 HP (150kW) motor and operate it for 20 years, with and without a VFD. Your total cost of ownership is as follows:

Line Driven Motor (no VFD)

- Electricity: $855,000

- Downtime from repair (1 x in the 20-year period): $47,500

- Rebuild costs (1 x in 20 years): $38,000 (removal, repair, replacement, alignment, labor)

- Cost of the new motor: $10,000

Total cost of ownership over 20 years: $950,500

Now let's compare this to a motor with a VFD but no shaft grounding ring

- Electricity: $570,000 (VFD saves 30% in energy costs)

- Downtime costs: $190,000 (4 x motor failure from fluted bearings)

- Rebuild costs: $152,000 (removal, repair, replacement, alignment, labor)

- Cost of Motor + VFD: $20,000

Total cost of ownership over 20 years: $932,000

Last, let's compare the VFD driven motor with a shaft grounding ring installed.

- Electricity: $570,000 (you still get the savings!)

- Downtime costs: $47,500 (1 x in 20 years - nothing lasts forever!)

- Rebuild costs: $38,000 (1 x in 20 years - you eliminated the frequent bearing failures!)

- Cost of the Motor + VFD + Bearing Protection: $22,000

Total cost of ownership over 20 years: $677,500: You save $273,000 on this 200 HP (150kW) motor

The savings are proportional to the power (hp/kW) rating of the motor, so now ask yourself:

- How many motors do I have in my facility?

- How many are on VFDs?

- How many will be operated by VFDs in the next 10 years?

- Do all my motors have bearing protection (shaft grounding rings) installed?

- Does my motor and drive specification require shaft grounding rings on the motors?

And last but not least: If all of your motors had bearing protection,

- How much money would I save?

- How much more profitable would my operations be?

- Can I really afford NOT to specify motors with shaft grounding rings installed?

Choosing a New Electric Motor

When you purchase new motors, the easiest solution is to select models that already have a shaft grounding ring installed by the manufacturer. There are many options for this from most motor manufacturers, such as Baldor (ABB); U.S. Motors (Nidec); WEG Electric; Marathon; LEESON; TECO-Westinghouse; and GE Industrial Motors (Wolong). For motors already in service, whenever a motor is re-wound or repaired by a motor repair shop, a shaft grounding ring should be installed at the same time.

Whether factory-installed or fit in the field, AEGIS Shaft Grounding Rings also have a 2-year extended warranty against bearing fluting damage. No other form of shaft grounding offers a warranty like this.

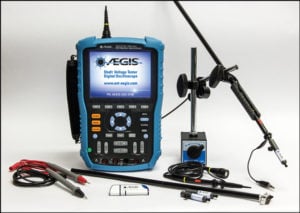

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and – pandemic restrictions permitting – we can also visit your facility to review your exact application.