Is Your Motor at Risk of Bearing Damage? Find Out with the AEGIS® Shaft Voltage Tester!

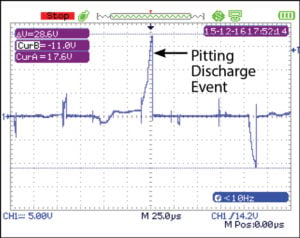

If you are controlling motors with variable frequency drives (VFDs) - aka variable speed drives (VSDs) or inverters - those motors are at risk of electrical bearing damage. VFDs convert pure sine wave power into a series of positive and negative pulses that combine to induce capacitive voltages on motor shafts. Without a safe path to ground, these shaft voltages can discharge through motor bearings and, through the process of electrical discharge machining, or EDM, will destroy the bearings — often in as few as 3 months!

If you are controlling motors with variable frequency drives (VFDs) - aka variable speed drives (VSDs) or inverters - those motors are at risk of electrical bearing damage. VFDs convert pure sine wave power into a series of positive and negative pulses that combine to induce capacitive voltages on motor shafts. Without a safe path to ground, these shaft voltages can discharge through motor bearings and, through the process of electrical discharge machining, or EDM, will destroy the bearings — often in as few as 3 months!

According to NEMA MG1 Part 31.4.4.3, capacitive shaft voltages of 10-40 volts peak (or 20-80 volts peak-to-peak) can cause electrical discharges in motor bearings.

The best time to test for damaging shaft voltages is as soon as motors are put into operation — right after new motors are installed, immediately after a damaged motor is repaired or its bearings are replaced, or upon commissioning of motors in newly constructed buildings or installation of new production equipment.

But it's not always easy to convince building owners or managers of the need for shaft grounding before an actual problem — and the expense of fixing it — arises. And until now, the only way to test motors and document whether they were at risk of bearing damage was to buy or rent an oscilloscope and make or buy some sort of shaft voltage probe.

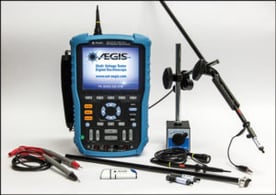

Now, the AEGIS® Shaft Voltage Tester comes complete and specially configured — right out of the box — with everything you need to take and record accurate voltage readings from the spinning shafts of motors. In fact, the Shaft Voltage Tester's screen capture feature lets you save actual voltage readings to a USB drive for subsequent analysis and presentation, providing proof to building owners or corporate management of the need for shaft grounding.

So don't wait until you need to repair or replace damaged bearings before checking to see if your motors are at risk. Test them as soon as they are operational with an AEGIS® Shaft Voltage Tester. And if they are at risk, protect them with AEGIS® Shaft Grounding Rings.

Special Offer:

From now until the end March, 2018, if you purchase an AEGIS® Shaft Voltage Tester with an extended warranty (AEGIS-OSC-9100-W2), Electro Static Technology will include a probe holder, a magnetic base, a shaft grounding simulator (to demonstrate how an AEGIS® Ring would reduce the shaft voltage), and 3 extra shaft voltage probe tips — a $336 value — at no charge! Testers typically ship within 2 days of order.

From now until the end March, 2018, if you purchase an AEGIS® Shaft Voltage Tester with an extended warranty (AEGIS-OSC-9100-W2), Electro Static Technology will include a probe holder, a magnetic base, a shaft grounding simulator (to demonstrate how an AEGIS® Ring would reduce the shaft voltage), and 3 extra shaft voltage probe tips — a $336 value — at no charge! Testers typically ship within 2 days of order.

In addition, your local AEGIS® representative will provide free training on the use of the Shaft Voltage Tester — at your facility and at your convenience — free of charge!