Best Practices for Bearing Protection

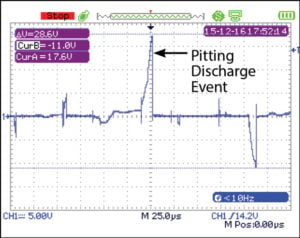

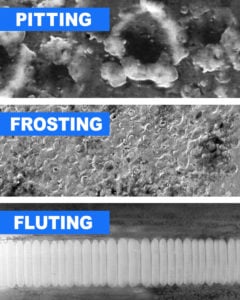

In our last post, we described how VFDs cause electrical bearing damage. So, how do you protect motors from this damage?

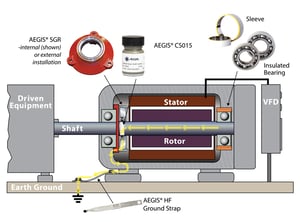

Capacitive EDM currents come about because of the shaft voltage, the voltage difference between the rotor and the frame. This voltage difference drives electrons through the bearings. But you can short circuit this effect and prevent EDM current by providing an alternative, low-resistance path from shaft to frame. AEGIS® Shaft Grounding Rings provide such a path, allowing electrons to flow harmlessly between the shaft and frame.

For low-voltage motors (up to 100 hp/75 kW), the best practice is to install an AEGIS SGR to discharge capacitively induced shaft voltage. The ring can be installed internally or externally, at either the drive end or non-drive end of the motor.

For motors greater than 100 hp/75 kW, capacitive EDM current will still be present, but now high-frequency circulating currents will occur as well. The best way to prevent HF circulating currents is to interrupt them with insulation or isolation of the bearing at the opposite end from the AEGIS ring. So for motors between 100 and 500 hp (75-375 kW), the best practice is to install an AEGIS SGR on the drive end, and isolate the bearing on the non-drive end to disrupt circulating current. This isolation can be done with an insulating sleeve or coating, or an insulated ceramic or hybrid bearing.

For motors greater than 100 hp/75 kW, capacitive EDM current will still be present, but now high-frequency circulating currents will occur as well. The best way to prevent HF circulating currents is to interrupt them with insulation or isolation of the bearing at the opposite end from the AEGIS ring. So for motors between 100 and 500 hp (75-375 kW), the best practice is to install an AEGIS SGR on the drive end, and isolate the bearing on the non-drive end to disrupt circulating current. This isolation can be done with an insulating sleeve or coating, or an insulated ceramic or hybrid bearing.

For low-voltage motors greater than 500 hp/375 kW, and medium-voltage motors, use an AEGIS PRO Ring instead of an SGR.

For motors with both bearings insulated, the driven equipment's bearings are at risk. So we recommend installing the appropriate AEGIS ring (SGR or PRO) on the drive end. This will keep induced shaft voltage from discharging through the equipment's bearings.

Regardless of the type of AEGIS ring or where you install it, we also recommend that you apply AEGIS Colloidal Silver shaft coating to the motor shaft in the area where the ring's conductive fibers will contact it. Colloidal Silver improves the shaft surface's conductivity and helps the AEGIS ring work.

Regardless of the type of AEGIS ring or where you install it, we also recommend that you apply AEGIS Colloidal Silver shaft coating to the motor shaft in the area where the ring's conductive fibers will contact it. Colloidal Silver improves the shaft surface's conductivity and helps the AEGIS ring work.

AEGIS Rings also come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and - pandemic restrictions permitting - we can also visit your facility to review your exact application.